Green Smart Manufacturing | Intelligent Busbar Processing System Promoting Low Carbon Transition

Release time:

2024-07-23 09:50

Source:

Based on the new stage of development, the implementation of the new development concept, the "14th Five-Year Plan" comprehensive programme of energy conservation and emission reduction, said to promote a substantial increase in the energy utilization rate, a sustained reduction in the emission of major pollutants, and to achieve synergies between energy conservation, carbon reduction and pollution reduction.

Under the dual drive of global energy transition and environmental protection, China's equipment manufacturing technology field is moving towards a new era of green low-carbon at an unprecedented speed. As a key link in the power transmission and distribution system, the development of the busbar industry by the government's high attention and policy support, a huge market space provides an excellent opportunity for its development.

But in the current busbar processing and production areas, despite the continuous progress of technology, we are still facing many problems and challenges.

1

Conventional processing methods are generally high energy consumption, low efficiency and with other issues, undoubtedly increasing the operating costs of enterprises, and restricting wheir ability to sustainable development.

2

The traditional production process lacks intelligent management, which makes it difficult to improve processing precision and efficiency, leading to uneven product quality, and also lacks innovation in energy-efficient design.

3

With increasingly stringent environmental protection policies, enterprises are facing increased pressure to reduce emissions, such as the current policy requires that energy consumption and carbon dioxide emissions per unit of GDP be reduced by 2.5 per cent and 3.9 per cent, respectively.

In this green revolution, the superior energy-saving performance and intelligent design of Hiprecise busbar intelligent processing system has undoubtedly become a major highlight in the industry. Driven by technological innovation, the system proposes a comprehensive and effective solution to the pain points of traditional busbar processing and production.

Green Intelligent Manufacturing, Efficient Leadership

01

Energy saving and precise control of the whole machine

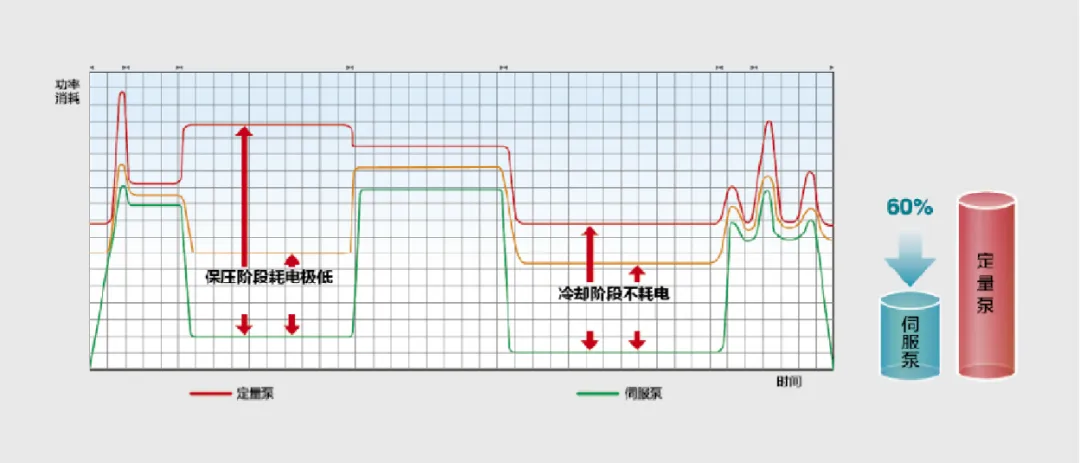

Hiprecise's intelligent busbar processing system achieves whole machine energy saving of about 50% through in-depth optimisation of structural design. This achievement is mainly attributed to its high-efficiency motor and drive system, which can accurately sense and respond to processing needs and flexibly adjust power output. This intelligent energy management strategy not only guarantees processing quality, but also reduces energy consumption at the source.

In particular, the punching and shearing section adopts a servo-hydraulic system, which can be intelligently adjusted according to the processing demand. Combined with the optimised pressure and flow control algorithms, it achieves on-demand start-up and precise oil supply, saving more than 60% energy compared with the traditional equipment, and realising a real sense of reduction in costs and increase in efficiency.

02

Real-time monitoring, intelligent management

In order to further improve the level of energy efficiency management, Hiprecise busbar intelligent processing system can also be equipped with intelligent energy consumption management system. The system comes with real-time monitoring and intelligent adjustment of equipment running status to ensure that the equipment is always in the best working range and energy consumption is under control.

03

Space optimisation, efficiency improvement

Hiprecise busbar intelligent processing system not only excels in energy saving, but also shines in its compact structure design. The mainframe occupies an area of only 2.8*7.8m, which effectively saves production space, reduces enterprise operating costs, and at the same time improves production efficiency and layout flexibility. These advantages make it an ideal choice for optimising production layout and improving efficiency.

Intelligent technological innovation has become the core driving force for the busbar industry to leap forward, while the concept of energy-efficient product design will become the mainstream beacon for the development of the industry. With its superior performance, Hiprecise's busbar intelligent processing system not only greatly improves the operating efficiency of the equipment and achieves a significant reduction in energy consumption, but also more accurately meets the urgent needs of modern electric power enterprises for intelligent, real-time monitoring and control.

In the future, Hiprecise will continue to devote itself to technological innovation and green development, and continuously optimise product performance and service quality to bring you more high-quality, high-efficiency and environmentally friendly solutions. We look forward to working with you to create a better and more sustainable future.

Related News

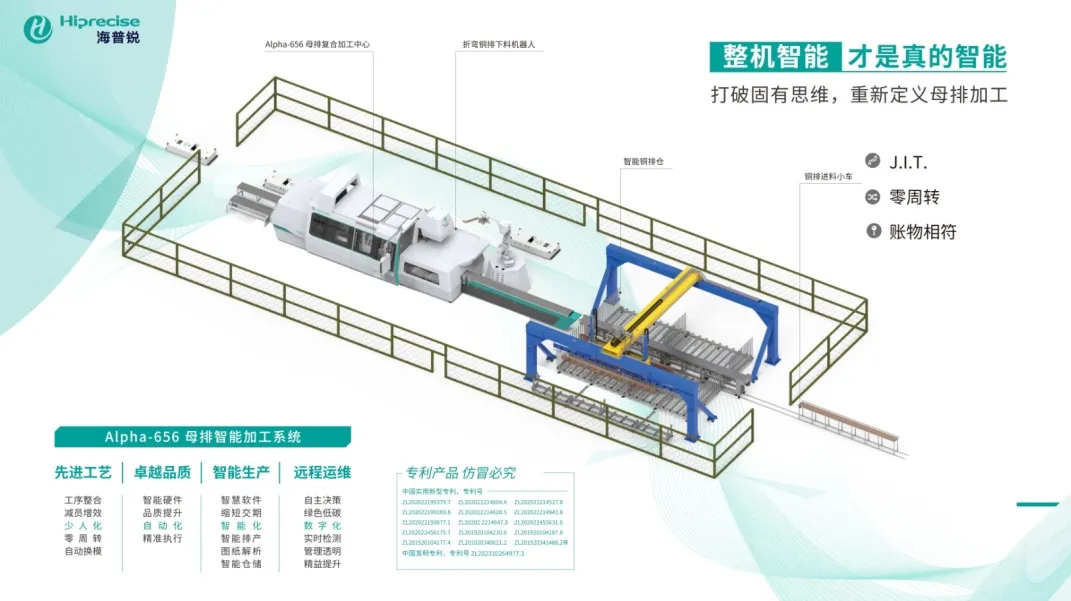

Haipuri Alpha-656 Busbar Intelligent Manufacturing System Solution

Break the conventional thinking, redefine busbar processing, and true intelligence lies in the overall machine intelligence.

Xiamen Haipuri, as a national-level specialized and innovative 'little giant' enterprise, was invited to participate in the 2024 EP exhibition, showcasing the innovative achievements of Haipuri's digital intelligent equipment empowering new quality productivity in the power sector.

HPC-9060 Fully Automatic Numbering Tube Terminal Crimping Machine

6 lines 4 pipes automatic switching, high flexibility, intelligent

HPC-8080 Fully Automatic Terminal Crimping Machine for Numbered Tubes

2-line 2-tube automatic switching practical type, fully optimized and efficient

Recently, the Xiamen Municipal Bureau of Industry and Information Technology officially released the '2024 Advanced Manufacturing Industry Doubling Plan Enterprise List', and Haipuri was selected for the 2024 Advanced Manufacturing Industry Doubling Plan Enterprise List.

Hiprecise sincerely invites you and looks forward to your presence!