Haipuri Alpha-656 Busbar Intelligent Manufacturing System Solution

Release time:

2024-12-21 15:22

Source:

1 Solution Overview

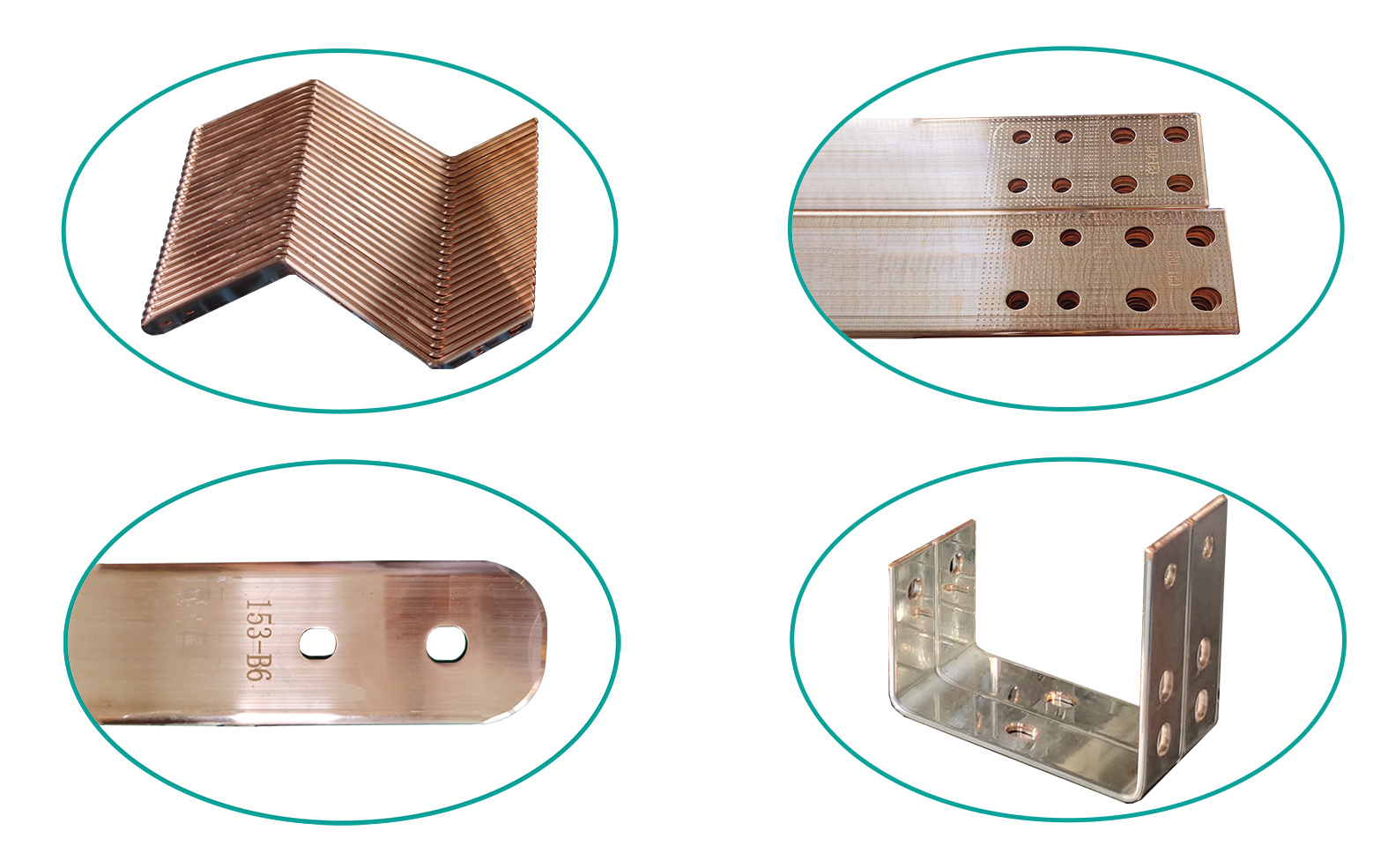

Crafted with ingenuity by HaipuriAlpha-656Intelligent Manufacturing Solution for Busbars, integrating and merging busbar processing procedures, combining drawing analysis, material feeding, laser printing, punching, shearing, embossing, corner milling, bending, and blanking into one system to create a one-stop high-flow processing solution that achieves true intelligent manufacturing of busbars and helps industry clients enhance their competitiveness.

2 Solution Features

1 Intelligent System for the Whole Machine

- Integrated smart software+and intelligent hardware to achieve intelligent processing of busbars.

2 Proprietary AI Algorithms

- Self-developed busbar sketching software for rapid production of three-dimensional models of busbars.

- Two-dimensional and three-dimensional drawing analysis can automatically convert into equipment processing codes.

3 Process Integration Highly Integrated Small Footprint

- Integrating traditional busbar processing procedures such as punching, corner milling, bending, etc.

- The footprint is only22x3m(Composite main machine+(Standard warehouse))

4 Intelligent Warehousing Smart Logistics Achieving Automated Transportation

- Achieving automation in loading and unloading of busbars effectively reduces labor intensity.

- Digital empowerment for precise control to ensure consistency between accounts and inventory.

- Automatic nesting improves efficiency and accuracy.

5 Fully Automatic Corner Milling/Laser Marking

- 'Mirror-like' finishing effect; after corner milling, the surface roughness of the copper bar reaches 'Ra 0.8'

- , supporting dry milling at both ends of the copper bar./, wet milling.6(Secondary) Automatic Tool Switching for Milling Tools

- 'Full servo system' +High-precision electric spindle control with self-energy saving.1/3

- Using automatic laser marking to identify copper bar parts; flexible settings for marking position angle and content; supports characters and QR codes.

6 Advanced Punching Shearing Technology New Bending Technology

- Controlled by a full servo hydraulic system; increased mold life.3times

- No manual deburring required after punching.

- High-precision continuous bending with no creases after bending; equipped with visual inspection.

7 Multiple Copper Bar Discharge Methods

- Single Punch/Punch-Milling Straight Discharge

- Bending Copper Bar Robot Unloading

8 Machine Vision Technology Real-time Monitoring to Ensure Quality

- Supports real-time detection and non-contact detection.

- High-precision detection ensures product quality.

9 Precise Actuators Achieve Precision Processing

- Whole machine full servo control system.

- High-precision positioning technology accurately identifies the position and size of copper bars.

- Precision punching shearing bending molds.

10 Intelligent Operation & Maintenance Cloud-based Equipment Management Helps Monitor System Operation Status

- Real-time data monitoring provides timely feedback on issues to improve production efficiency.

- Data analysis optimization deeply explores and analyzes empowering enterprise production.

- Remote maintenance management improves equipment availability and stability.

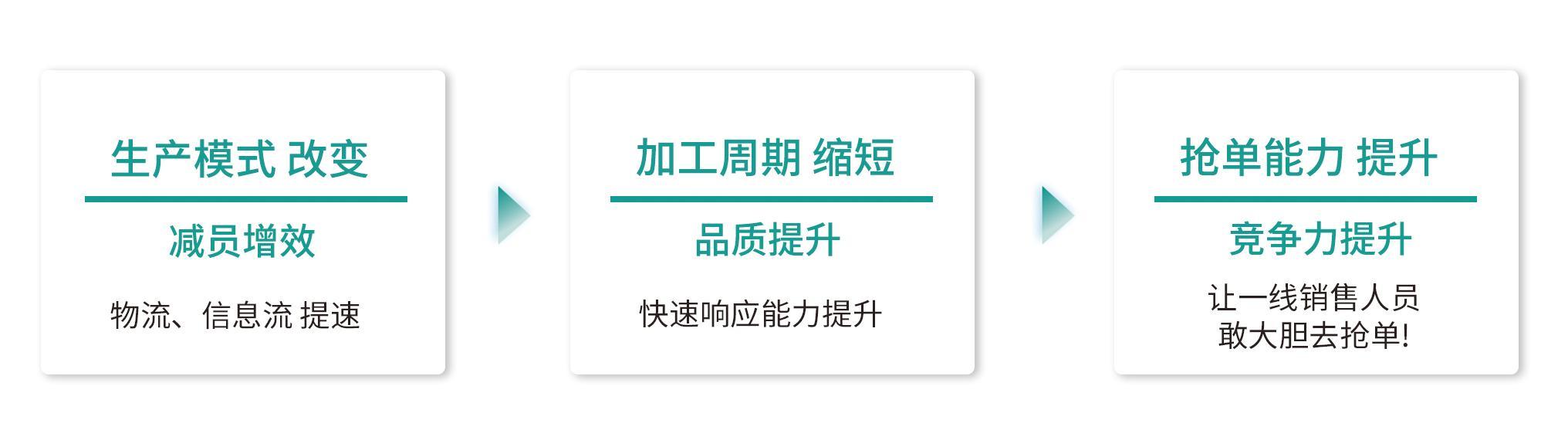

3 Product Advantages

4 Product Parameters

Related News

From DeepSeek to Core Value Mining of Large Models

The group standard "General Requirements for Automotive Low-Voltage Wiring Harness Processing Centers", spearheaded by Haiprui, provides comprehensive and detailed regulations on the technical requirements, operating specifications, and quality control of automotive low-voltage wiring harness processing centers. It offers unified technical guidance and standardization for relevant enterprises in the industry.

Haiprui assists Tianjin Tebian Electric Apparatus in production line debugging

Haiprui assists Tianjin Tebian Electric Apparatus in production line commissioning

Recently, Zhenjiang Daquan's high-voltage switchgear project for Saudi Arabia's Qassim and Taybah regions was successfully shipped. This was facilitated by Haiprui's HPC-9060 intelligent processing center for secondary lines and Alpha-656 intelligent busbar manufacturing system.

Hapurui showcased its automotive electronics intelligent manufacturing solutions and latest products and technological achievements, including many star solutions such as automated insert molding, fully automated hinge (compression), high-speed communication lines, and new energy high-voltage lines.