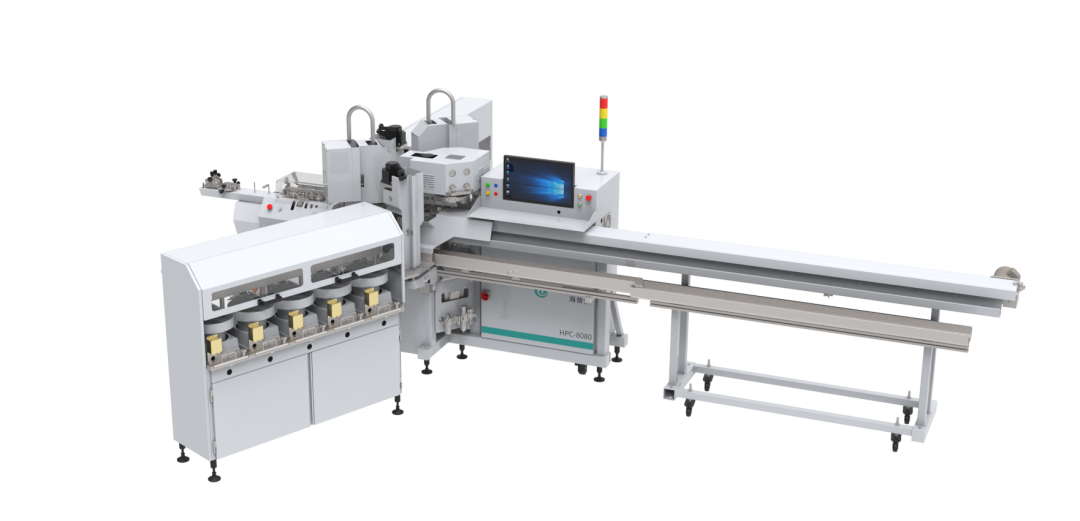

HPC-8080 Fully Automatic Terminal Crimping Machine for Numbered Tubes

Release time:

2024-12-02 10:48

Source:

Project Overview

HaipuriHPC-8080 Fully Automatic Terminal Crimping Machineis based on our company's2014invention from years agoHPC-8040in the electrical assembly industry500+years of practical experience with customers, specifically developed practical equipment. Suitable for fully automated production of secondary line tube printing and terminal crimping.

Project Features

■ Efficient

- Software supports intelligent scheduling to maximize productivity

- Processing parameters can be loaded with one click, reducing data entry time

- Batch processing production efficiency can reach up to750pieces/per hour

■ Flexible

- 2Group wire feeding system, automatic switching

- 20for different terminal types produced independently without mold change (if expansion is needed, the vibrating plate can be quickly replaced)

- Innovative dual-tube terminal machine automatic switching

- compatibleBVR/RVwith wire processing, processing wire diameter0.5-4mm²

- Software integration: can handle wire processing work orders generated by third-party software, forming a complete secondary offline solution

- The new terminal crimping machine adopts a tool library management mode (up to24sets of crimping jaws can be configured), mold-free production

■ High Quality

- Terminal feeding system: adopts the latestXYaxis robotic arm+vibrating plate terminal feeding technology, reducing friction between terminals, effectively ensuring the coating of terminals

- Wire feeding system: adopts belt feeding method, ensuring no damage to the wire surface

- Alarm module monitors the production process in real-time, preventing defective products from flowing into the next process

- Moving parts are protected by independent protective covers to ensure safe production

■ Savings

- Power consumption per product is significantly reduced

- Automatic switching between dual wires, dual tubes, and20mold-free design for different terminal types saves compared to general equipment in the industry1/3up to1/2in personnel

■ Stable

- Stable and reliable flexible operating system: has500+terminal customers in the electrical assembly industry, ensuring the equipment does not crash and can operate continuously and stably

- Key purchased components use internationally renowned brands

- Key components are independently designed and manufactured, ensuring precision and interchangeability of parts

■ Safe

- Equipped with safe and reliable operating functions, isolation devices, effectively isolating dangerous areas before startup

- Emergency stop buttons are available in the safe operating area

- Straightening mechanisms are configured at the wire entry end to prevent twisting during processing

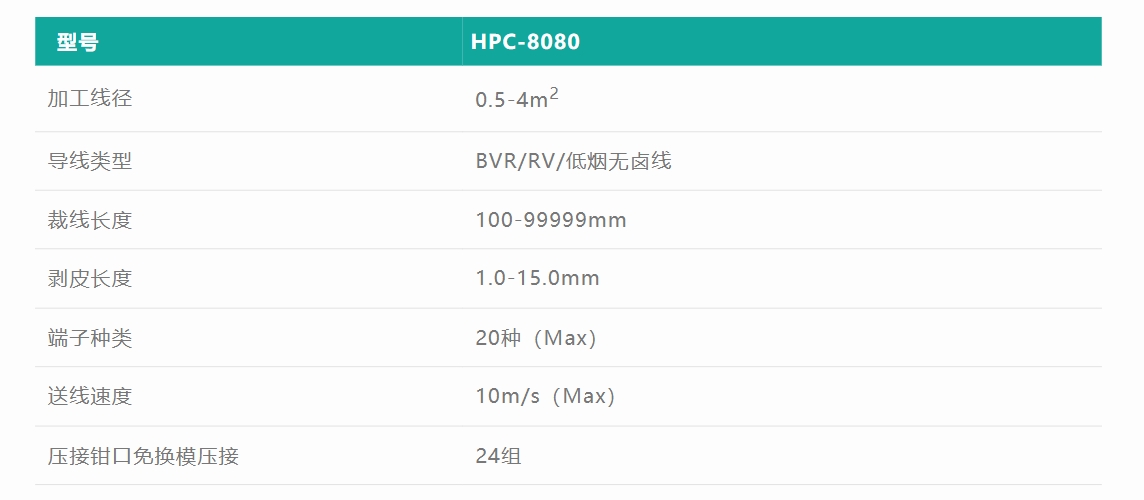

Product Parameters

Related News

Haipuri Alpha-656 Busbar Intelligent Manufacturing System Solution

Break the conventional thinking, redefine busbar processing, and true intelligence lies in the overall machine intelligence.

Xiamen Haipuri, as a national-level specialized and innovative 'little giant' enterprise, was invited to participate in the 2024 EP exhibition, showcasing the innovative achievements of Haipuri's digital intelligent equipment empowering new quality productivity in the power sector.

HPC-9060 Fully Automatic Numbering Tube Terminal Crimping Machine

6 lines 4 pipes automatic switching, high flexibility, intelligent

HPC-8080 Fully Automatic Terminal Crimping Machine for Numbered Tubes

2-line 2-tube automatic switching practical type, fully optimized and efficient

Recently, the Xiamen Municipal Bureau of Industry and Information Technology officially released the '2024 Advanced Manufacturing Industry Doubling Plan Enterprise List', and Haipuri was selected for the 2024 Advanced Manufacturing Industry Doubling Plan Enterprise List.

Hiprecise sincerely invites you and looks forward to your presence!