CCD visual inspection technology can monitor the wire processing in real time, through advanced image processing algorithms to quickly provide inspection results, effectively identify and reject defective products in a timely manner to ensure quality

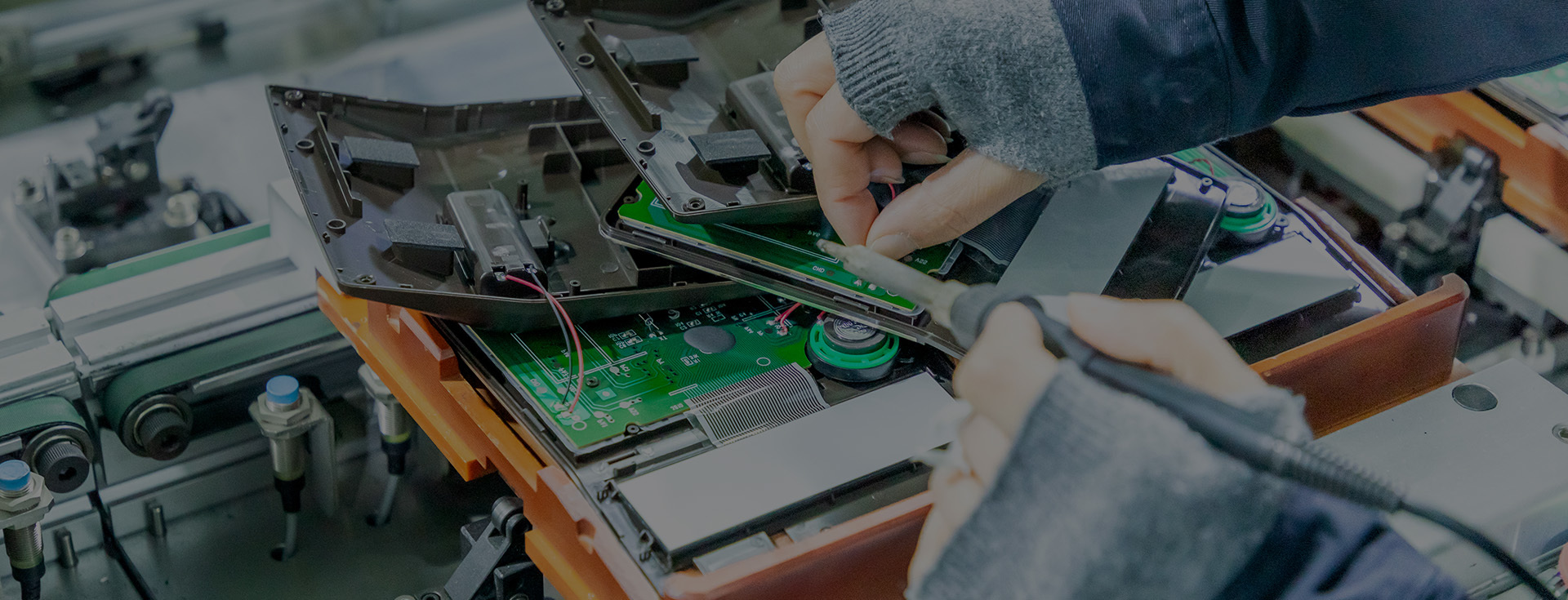

HiCFM-02 force management device

HiCFM-02 ensures the consistency of product quality through real-time monitoring of the pressure generated during the terminal pressing process.

The dimensional inspection device detects the dimensions of the terminal before and after crimping, as well as the dimensions of the stripping length to ensure that they are in compliance with the standards.

Depth inspection device can use the probe to detect the size of the centre pin and the outer conductor end face, to reject defective products in time to ensure quality.