Welcome to the official website of Hiprecise!

HIC-650

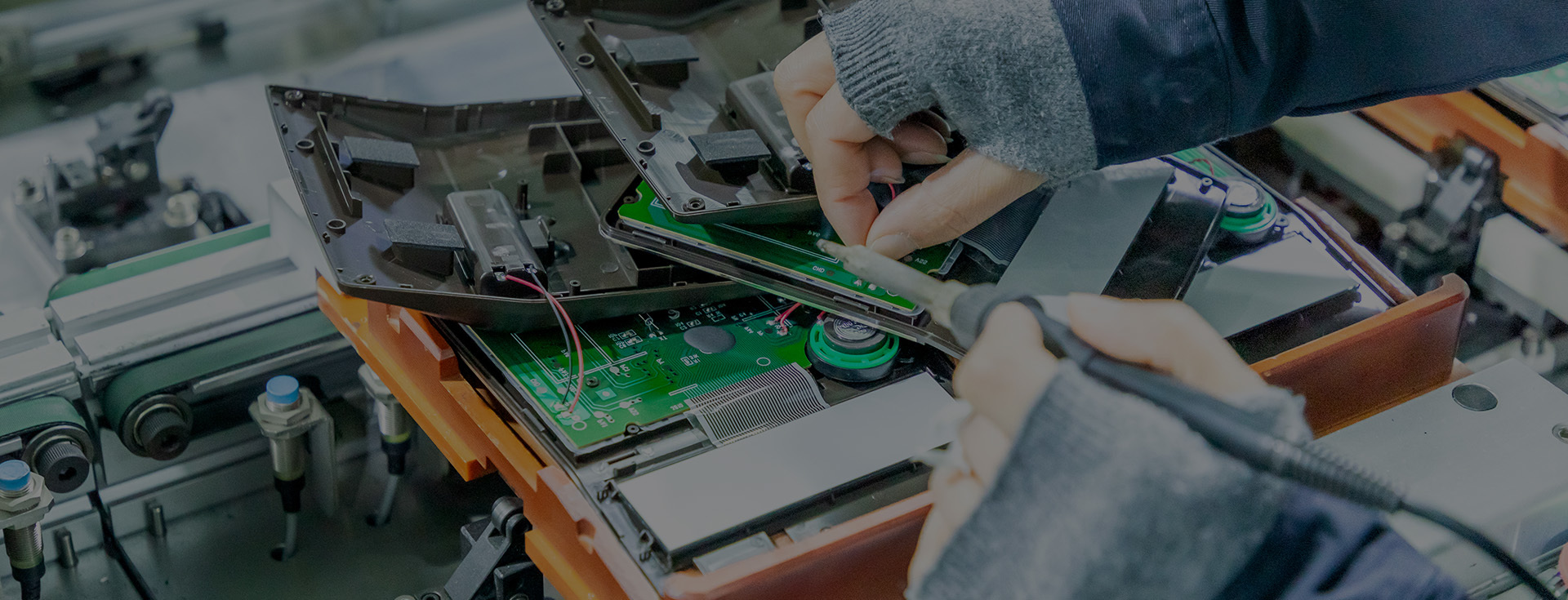

Fully automatic large square wire heat-shrink tube inserting and terminal crimping machine

large square line

full-automatic

heat shrinkage

cutting and stripping

seal inserting

HIC-650 can achieve the heat-shrink tube inserting process of large-square wires.

Classification:

Finished product display

Product Brief

HIC-650 fully automatic large square wire heat-shrink tube inserting and terminal crimping machine is specialized for 6-16mm²wires and provides two types of flexible processing modes: firstly, side A sealing and chained terminal crimping, side B optional heat-shrink tube inserting and chained/loose terminal inserting, which is applicable to various scenarios; secondly, side A/B both heat-shrink tube inserting and loose terminal crimping, achieving standardized processing and improving quality. The equipment adopts 6-axis robot + tray / flexible vibratory tray for automatic feeding, efficient and accurate. The equipment is integrated with heat-shrink tube positioning and heat-shrink station, with powerful functions to assist effective production.

Full-Process Automated Manufacturing

- Integrates all processes such as automatic wire feeding / cut and strip / seal inserting / terminal crimping / heat shrinkage.

- Compatible with 6-16mm² large wires

- Supports both end chained or loose terminal crimping

- Intelligent heat-shrink tube positioning and heat-shrink process

Flexble quick-switch system

- Quick-switch for wires / seals / heat-shrink tubes / terminals

- Formulated management, one-click for switching product parameters

- Time for applicator switching is shortened by more than 70%

Intelligent Quality Control System

- Supports seal inserting in-place detection, real-time monitoring of crimp force, CCD three-station visual inspection

- Accurately discharges defect products

Humanized Operation Experience

- Industrial touch screen with simple operation pattern

- Intellectualized fomula management

- Prompt of self-diagnosis of malfunction

Machine Parameters

|

Machine model |

HIC-650 |

|

Processing diameter |

4-16mm² |

|

Cut length |

150-3000mm |

|

Strip length |

1-15mm |

|

Length of heat-shrink tube |

25-45mm |

|

Terminal crimping ability |

8.0Ton 40mm stroke |

|

CMK of terminal crimping |

≥2.0 |

|

Cycle |

6s/pcs (Calculated by given condition that 4mm² wire, one side sealing and crimping, another side heat-shrink tube inserting and crimping) |

|

Detection functions |

Missing wire detection, missing terminal detection, CFM, CCD |

Related Products

online message

Address: No. 1, Jixiang West Road, Tong'an District, Xiamen City, Fujian Province, China

Telephone: 0086 0592-7115531

Email: sales@hiprecise.com

公众号

公众号

抖音号

抖音号

抖音号

抖音号

微信号

微信号

Message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

SAF Coolest v1.3.1.2 设置面板 GAGSX-ZGYF-JSAQE-SZX

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page