Welcome to the official website of Hiprecise!

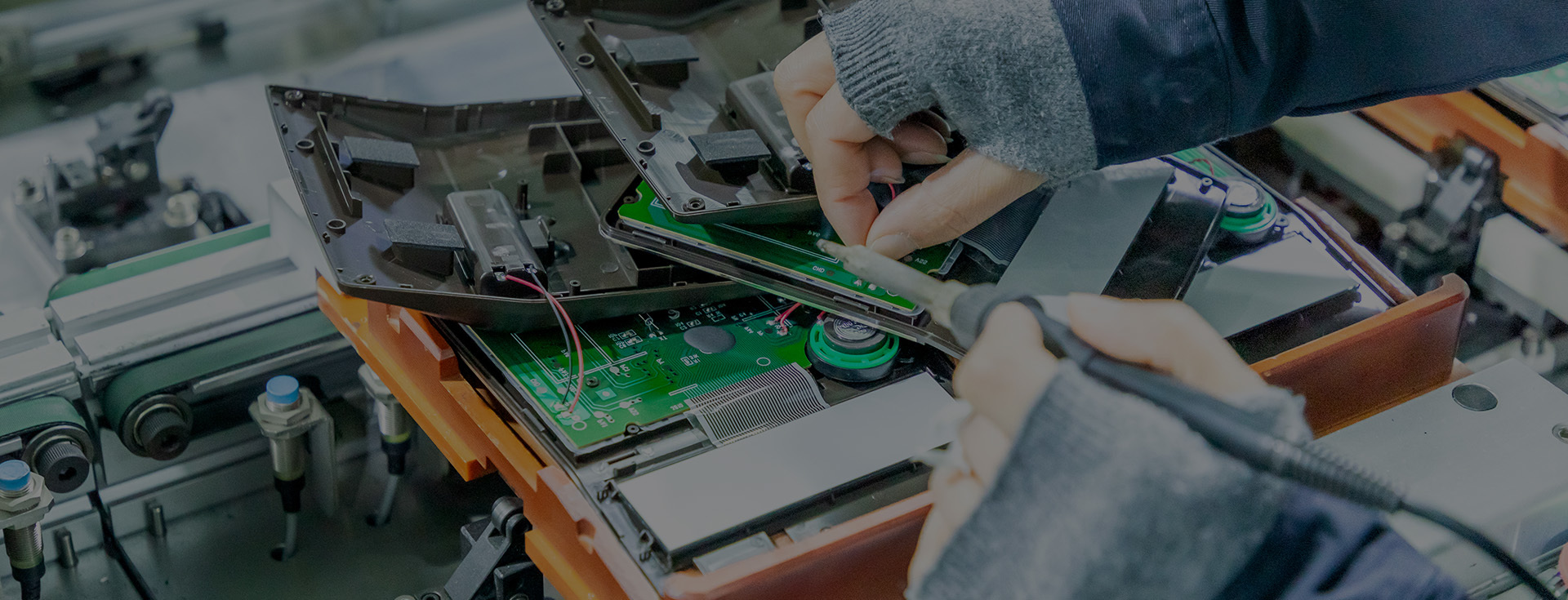

New energy high-voltage cable automation solutions

New energy

automation

high-voltage cable

modular and flexible

High-voltage cable automation production line has modular, highly flexible characteristics, can achieve the station module combination, the main functions are modular seal inserting, outer insulation rotary cutting, laser removal of aluminium foil, shield cutting, shield flip-over, inner insulation rotary cutting, inner and outer ring assembly, shield ring crimping, terminal ultrasonic welding, terminal crimping, heat-shrink tube inserting, housing assembly, and so on. Modular design makes it easy to replace the module quickly after product replacement and upgrading, which improves the compatibility of the production line.

Classification:

Finished product display

▪ Full-automatic processing of all workstations, drastically reducing the number of production workers.

Flexible Design

▪ The standard design of all workstation modules enables workstation replacement, allowing the production line to match product updates.

Quality Assurance

▪ All key process inspections (visual detection, pressure detection, crimp height detection, insertion and extraction force detection), forming a closed loop for quality control.

Digitalization of production line

▪ The production line is equipped with MES and OEE system, which collects and displays information on production material management, quality management, equipment operating rate, etc., and the production data can be traced.

Product Parameters

|

Functions |

Back cover assembling, ring sealing, outer insulation stripping, laser aluminum foil removal, shield cutting, shield flip-over, shield ring crimping, inner insulation stripping, inner core wire crimping/ultrasonic welding, heat-shrink tube inserting, heat shrinking, sheath assembly, OK/NG product sorting, automatic collecting, etc. |

|

Applicable wire diameter |

3-95mm2 |

|

Cycle time |

Single wire end processing ≤ 15s (subject to actual product process) |

|

Stripping length |

Outer insulation stripping 0-100mm, inner insulation stripping 0-50mm (full/half stripping), stripping accuracy ± 0.3mm, cutter accuracy 0.05mm |

|

Laser to aluminum foil |

The retention length shall be ≤ 2mm from the root, and the shieldt and inner insulation shall not be damaged. |

|

Retained size of shield |

5-30mm |

|

Length of shield flip-over |

≤ 30mm, flipped evenly and neatly |

Related Products

online message

Address: No. 1, Jixiang West Road, Tong'an District, Xiamen City, Fujian Province, China

Telephone: 0086 0592-7115531

Email: sales@hiprecise.com

公众号

公众号

抖音号

抖音号

抖音号

抖音号

微信号

微信号

Message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

SAF Coolest v1.3.1.2 设置面板 GAGSX-ZGYF-JSAQE-SZX

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page